A piece of information from our experts for your business plan

Table of Content

- Evolution of cashew processing from manual to automated systems

- Growth in the industry caused due to automated systems

- Harvesting and Export-Import of cashews

- Cashew market

- Key points to start a cashew processing plant

- Planning the layout for a cashew nut processing factory

- Setting up a plant

- Safety measures

- Tips on running a cashew processing plant

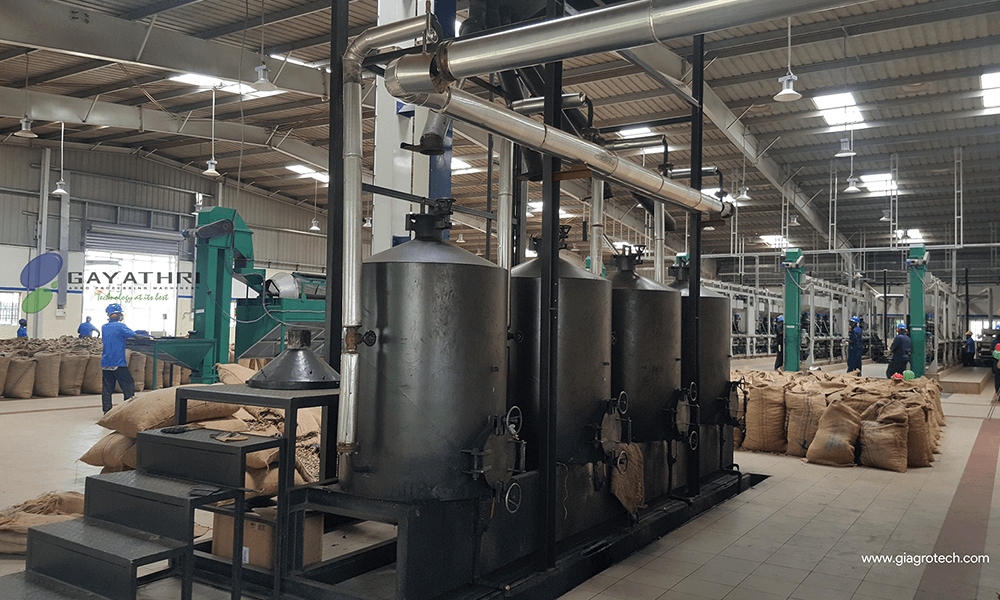

Evolution of cashew processing from manual to automated systems

Cashew nut processing has evolved from a manual process to an automatic process over the years. Cashew processing in India is more than a century old, and it started exporting cashew kernel way back in 1924 from Karnataka.

During the initial days of cashew processing, Sun-dried Raw cashew nuts(RCN) was oil roasted in Cashew Nutshell oil and shelled manually to obtain the cashew kernel. Later the cumbersome process of oil roasting was replaced with drum roasting in which Raw Cashew Nuts were roasted in a rotating heated drum and then shelled manually to get the kernel.

In the late sixties, Raw Cashew Nut's steam roasting before shelling emerged as a batch process in Mangalore.In the seventies, manual shelling was replaced by and & leg-operated shelling machine in Goa.

Traditional convection heating of skin on kernel was replaced in the 1980s by tray driers with electronic digital temperature and timer controllers with fans to maintain uniform heat circulation in the tray drier all through the drying process.

Tin packing was replaced in the 1990s with a multi-layer bulk pouch packing system that ensured proper preservation and ease of handling with an increased shelf life of packed kernels.

The early part of this century saw the invention of motorizedshelling machines that revolutionized the hazardous shelling of RCN in a big way.

The tedious, slow manual peeling of skin on the kernel was replaced with a pneumatic peeling system assisted by high-pressure air nozzles to peel the skin of the cashews.

Thus, cashew processing grew from a cottage Industry to a mechanized Industry attracting multi-National companies investing in cashew processing.

Growth in the industry caused due to automated systems

- Reduced dependency on skilled manual labor helped cashew grow in African nations, India and Vietnam, thus attracting significant investments in Cashew processing and exports.

- The total world production of Raw Cashew nuts stands at 4 million tons per annum. Increasing world demand for edible Cashew kernel and three-cornered need for raw nuts from India, Vietnam, and Africa lead to a phenomenal increase in nut prices, and raw Cashew Nut is now called Black gold.

This has caused erratic fluctuation in the Nut prices, attracting speculators entering nut trading in a big way in the recent past.

Harvesting and Export-Import of cashews

- Cashew nut season in India coincides with the mango season; it starts in April extends up to June.

- Cashew harvest season being different in different climate zones like East Africa, West Africa, and Indonesia makes Raw Cashew Nut available round the year for the processing Industry worldwide.

- Nuts harvested are processed and exported in about 3 months.

- For the rest of the year, to keep the processing going, Raw Cashew Nut is imported in a big way from other continents, particularly Africa &Indonesia.

Cashew market

- Brazil was the world leader in Cashew Nut processing until the early last century, and India overtook in the latter half of the previous century.

- Vietnam entered cashew plantation and processing towards the end of the last century and has emerged as a cashew processing and exports leader.

- The labor shortage to meet the growing demand for cashew kernel for export and increased consumption in India paved the way for mechanization in cashew processing.

- The price of Raw Cashew Nut keeps changing with market demand. The cost of finished edible cashew kernel is decided by the basket of tree nuts available for consumers in the world market.

- Cashew kernel is in high demand in North America & Europe as a snack food of high nutritional value and is mixed with other nuts like almonds, Brazil nuts, Chestnuts, Hazelnuts (filberts), Macadamia nuts, Pecans, Pine nuts (pinon, pignolias).Hence the price of Cashew kernel in the world market depends on the above basket of nuts.

- Thus, processers have no control over putting Raw Cashew nut and processed edible cashew kernel.

Key points to start a cashew processing plant

- Segment and target a market and do market research.

- Decision on from where to procure raw nuts for processing

- Know the capacity of the plant to layout types of machinery

- Human resource management

Planning the layout for a cashew nut processing factory

- Visit an existing cashew processing plant.

- Interaction with machine suppliers will lead to optimum plant use and smoothen the material handling process.

- Availing professional consultancy services like Plant layout consultancy and Turnkey Process consultancy from machinery suppliers.

Setting up a plant

Depending on the production capacity, you will need

- Land area

- Water

- Power

- Roads for transportation of goods

- Drying yard

- Warehouse

- Machines

- Labour

Safety measures

- Boilerhouse to be situated at a safe distance from the processing area.

- The plant shall have a hand and leg washing facility for the workers to access every time they enter the processing hall.

- The shelling of RCN, a low care area, is to be separated from medium care Peeling/grading & high care packing sections.

- Further resource requirements like electricity, soft water requirements for boilers, and other uses must be ascertained and planned.

Tips on running a cashew processing plant

- More machinery will reduce dependency on the labor force but at an increased investment cost.It is advisable to run 2 shifts with machinery for processing

- Keep all manual work involved in the general shift where women are primarily engaged. The above would lower capital investment and ensure a shorter pay-back period.

- Sound knowledge of Raw Cashew Nut quality assessment and sourcing at an economical cost is a must.

- Raw Cashew Nut being a seasonal product, the processor should keep sufficient stock of Raw material at least for 3 months, to begin with during the season.

- For further processing, RCN can be purchased from the local market or sourced from the Import market.

- The raw material warehouse shall have sufficient capacity to hold at least 3 months with a drying yard facility to sundry RCN.

- Train local technical talents, staff, and workers in processing skills and machinery maintenance with the help of skilled technicians taking help from machinery suppliers from machinery installation.

- Stock sufficient machinery spares to meet any exigency to avoid plant downtime.

- Ensure a proper marketing plan to focus on market requirements regarding quality/grade and packing of edible finished cashew kernel.

- Value addition to edible cashew kernel can ensure a better and quick return on investment – find market needs in terms of varieties of salt/spice coating requirements.

Hence the viability of Cashew Nut processing plants depends mainly on the procurement of Raw Nut at the right quality and price to have parity with edible kernel price produced in processing Raw Cashew Nut.

If you are looking to start a viable cashew processing business. We will provide the right solution as we have the right expertise.

GI Agro technologies - One-stop solution for all your cashew processing needs with state-of-the-art machinery. We are partners for life.