Introduction to Cashew Nut Processing Machine Unit

Raw Cashew Nut Processing as an industry has made rapid strides at the beginning of the 21st century with mechanization in Cashew processing.

Unit operations like steam roasting of RCN, Tray drying, steam Humidification in bulk have transformed the Industry from cottage level to mechanized Industry enabling processors to set up large capacity units.

Mechanized shelling has avoided hazardous & harmful effects of CNSL on workers. In addition, peeling mechanization has enabled cumbersome, laborious manual peeling to higher productivity & speed.

The optical color sorter has replaced hard-to-find highly skilled labor requirements for grading with high speed and accurate grading & sorting of kernels by optical color sorters. This has enabled us to pack sorted cashews for export straightaway, meeting stringent export quality standards.

Mechanization of shelling, Peeling, Grading, and packing of Cashew has enabled process cashew with the minimal workforce, say from 6.5 to 0.75 workers per bag of 80 kg input RCN.

Reduced reliance on highly skilled/trained labor has enabled African countries to promote cashew processing in a big way to add value to RCN harvested.

The mechanization has reached a level to meet the shortage of and or reliance on skilled workforce & achieve higher productivity. Moreover, it has helped the new African processors immensely to catch up with the years they have lost in processing skills knowledge by straight adoption mechanization and modern technology.

The mechanization of the Cashew Industry helped create job opportunities in a big way, add value to raw cashew nuts harvested, and earn forex for their country to boost their GDP.

Cashew kernel is obtained through processing as follows:

1. Raw Cashew Nut Pre-cleaning and De-stoning & sizing

Equipment needed

- Hydro or dry RCN pre-cleaner

- RCN sizing System for calibration.

Both wet & dry De-stoning system & RCN Sizing system capacity is customized and designed to suit the shelling capacity needed per hour.

Dust soil stones and immature nuts in the Raw Cashew Nut (RCN) interfere with mechanized shelling machines, causing damage and downtime. Hence RCN needs to be precleaned in a wet or dry de-stoning system to ensure uninterrupted shelling in machines.

RCN sizing (Calibration) is either done before or post steam cooking of RCN – to the processor's choice. RCN sizing is necessary as the shelling machines are designed sensitive RCN size for consistent optimum shelling yield Quality.

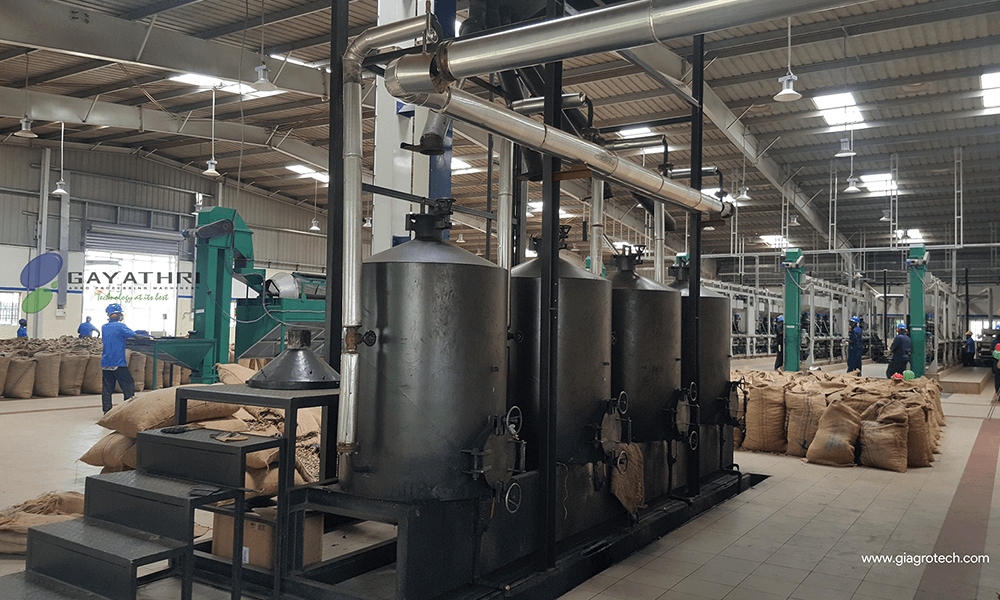

2. Steam Cooking.

Equipment needed

- Steam Boiler – for RCN steam cooking

- Cooker vessel

- Cooling silos

The capacity of the Steam boiler and cooker vessel is chosen to meet the shelling capacity required per shift.

Boiler steam also provides steam to the heating coil in the tray dryer – Borma and steam humidification of skin on the kernel.

Raw Cashewnut Precleaned, de-stoned, calibrated, & stored in the warehouse are steamed in the Boiler (Without steam pressurizing the cooking vessel) for about 10to 12 minutes. The steam cooking is carried out for a period depending upon the condition of the Cashewnut and prevailing atmospheric conditions. The steam cooking expands the shell covering the nut & softens the nutshell due to steam ingestion, moisturizing the nut replacing surface CNSL. After Steam cooking, the nuts are air-cured (cooled) overnight by spreading the nuts on the floor in the shade.

The steam cooking removes oil in the nutshell surface which interferes while shelling, expands the shell covering the cashew kernel embedded inside, and renders the shell hard and fit enough for shelling.

The steam preserves the original color of the cashew kernel embedded inside the nut—the cut shells of the steam cooking process yield quality Cashew Nutshell Liquid (CNSL).

Steam cooking is a batch process by infusing steam into the cooker vessel and draining the surface oil expelled by steam.

3. Shelling.

Equipment needed

- Mechanised shelling machine

- Mechanized vibratory sieve & pneumatic Shell separator

- Mechanized scooping system

- Color sorter to separate kernels mixed in shells on separation

The steam-cooked and air-cooled raw Cashew nuts are shelled in a motorized shelling machine by designated shelling line according to size for bulk production in an integrated shelling line equipped to separate shell & kernel after shelling. Also, uncut and un-scooped RCN with embedded kernels is separated with roller separators for further processing.

Mechanization enables the shelling of nuts up to scooping with 300,600 and 1200 kg per hour per shelling line, considerably reducing the workforce compared to manual shelling.

4. Borma Treatment.

Equipment needed

- Tray dryer, trolley & tray

- Steam supply from Boiler

- Moisture meter

After the shelling process removes the Kernels from the shells, the kernels need to be dried by hot air treatment to loosen the red skin (testa) adhering to the kernel for easy peeling (removal) of the non-edible red skin.

Steam is heated in bulk capacity dryers- 500 kg 1000 kg z000 kg per batch at about 75 to 80 degrees centigrade for about 10 to 12 hours per batch for bulk tray drying of shelled skin on kernels. Kernel moisture percentage is reduced to about 4 %

5. Humidification.

Equipment needed

- Steam humidity chamber

- Tray & trolley

- Moisture meter

- Supply of Steam from Boiler

The borma treated cashew kernels are steam humidified (moisturized) to about 5.5 %. The Cashew kernel trays are kept in trays and loaded to trolleys for a Steam humidifier in a closed room for a predetermined period depending on the atmospheric condition and the moisture level of the input kernel treated.

The humidified kernel's brown skin (testa) undergoes shrinkage due to sudden cooling after heat treatment. This helps dislodge the hold (adhesion) of the skin to the kernel in the Pneumatic peeling process.

6. Peeling.

Equipment needed

- Pneumatic Peeling machine with an air compressor

- Super calibrator for kernel sizing into wholes and pieces

- Color sorter to separate unpeeled /partially peeled kernels

Tray dried and steam humidified skin on cashew kernel is loaded into the pneumatic peeling machine input hopper.

Kernels are fed into a vertical cylinder and subjected to a high air pressure by a set of high-pressure air nozzles for a few microseconds to peel the kernel skin.

The peeling husk generated is removed, and the peeled kernel is collected at the bottom of the peeling machine.

The efficiency of the peeling machine is about 75 % fully peeled kernel, and broken generation is about 10 percent.

Unpeeled and partially peeled kernels are separated using a color sorter and are manually peeled.

7. Grading.

Equipment needed

- Optical Colour sorter with compressor and UPS

Cashew kernels are graded based on shape, size & color. International Specification and Standards are followed. The Grade Specification & Colour chart issued by Cashew Export Promotion Council of India has been recognized worldwide.

Optical cashew color sorter makes one selection at a time with very high speed and accuracy to meet the required standards of the kernel as programmed in the color sorter.

8. Conditioning

Equipment needed

- Moisture meter

- Tray dryer

- Humidifier

At the time of final packing, the moisture percentage permitted in the graded Cashew kernel is 3 to 5 % by weight as a higher moisture level above 5 % may cause fungi and aid infestation. On the other hand, a low moisture level is undesirable. It causes kernel breakage during transport—process control measures to be suitably deployed to control the moisture level between 4 to 5%.

To reduce excess moisture levels, cashew kernels are heat-treated and humidified to increase moisture to the required level, if needed.

9. Inspection & UV/IR sanitization

Equipment needed

- UV and IR Sanitation system

Cashew kernels graded and conditioned for final moisture level are visually inspected in an Inspection conveyor, rejects if any found are physically removed, and then passed through a X-ray foreign matter detector & magnetic detector for ferrous material detection.

Inspected and foreign matter-removed kernels are passed through the IR / UV sanitizing system to eliminate any infestation in kernels and ensure log reduction of harmful bacterial/ viral load necessitated by the present pandemic environment.

10. Kernel Filling & Packing.

Equipment needed

- Bulk pouch packing machine and gas ports for Carbon dioxide & Nitrogen ingestion

- Digital weighing machine

Both manuals weigh fill and seal machine & automatic weigh fill and seal machine is used.

Cashew kernel goes for final shipment packing immediately after IR/UV sanitation for bulk packing in multilayer pouches in 25 or 50 lbs. net weight packing (11.34 or 22,68 kg) in vacuumized and inert gases - Nitrogen & Carbon dioxide infused pouched and sealed airtight and put into cartons.

This ensures the prevention of infestation in a packed tin container and increases the shelf – life of Cashew kernel during shipment & storage until it is consumed.

Pouches 2 X 25 LBS or 1 X 50 LBS pouch is packed in a carton, strapped, and marked for export.