Raw Cashew Nut (RCN) Processes

Cashew kernel is obtained through factory processing as follows.

- Steam Cooking

- Shelling

- Borma Treatment

- Humidification

- Peeling

- Grading

- Conditioning

- Filling & Packing

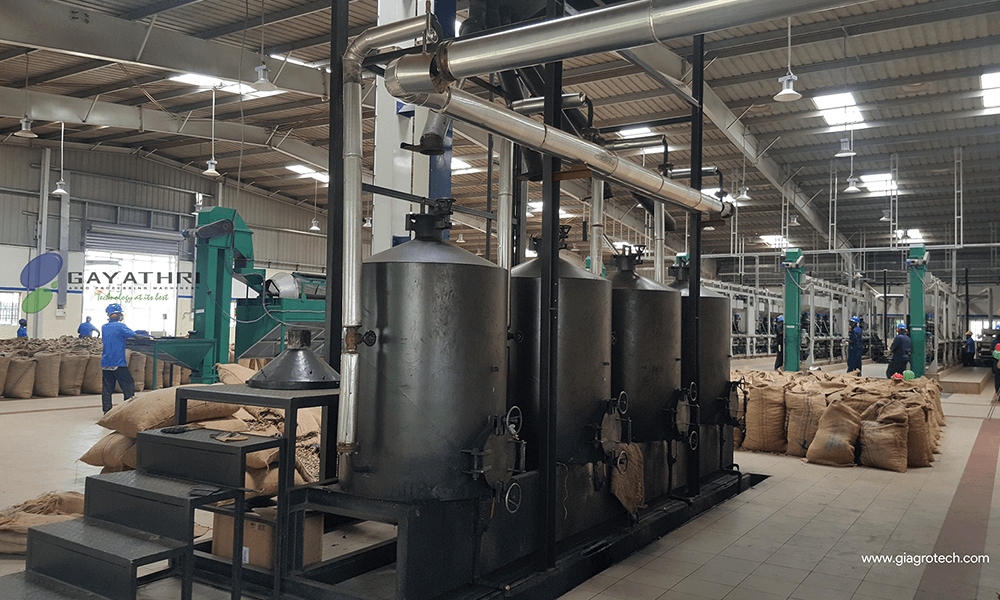

Steam Cooking Cashew Machine

Raw Cashewnut (RCN) that are sun-dried & stored in the Warehouse are steamed in a cooker vessel. The duration of steam cooking also depends upon the condition of the RCN and prevailing atmospheric conditions. The steam cooking expands the shell covering the RCN & hardens it due to ingestion of Steam. After Steam cooking, the nuts are air-cured (cooled) overnight by spreading the nuts on the floor in the shade.

The steam cooking removes excess surface oil in an RCN, expands the cashew kernel's shell covering, and hardens the shell fit enough for shelling to get the Kernel.

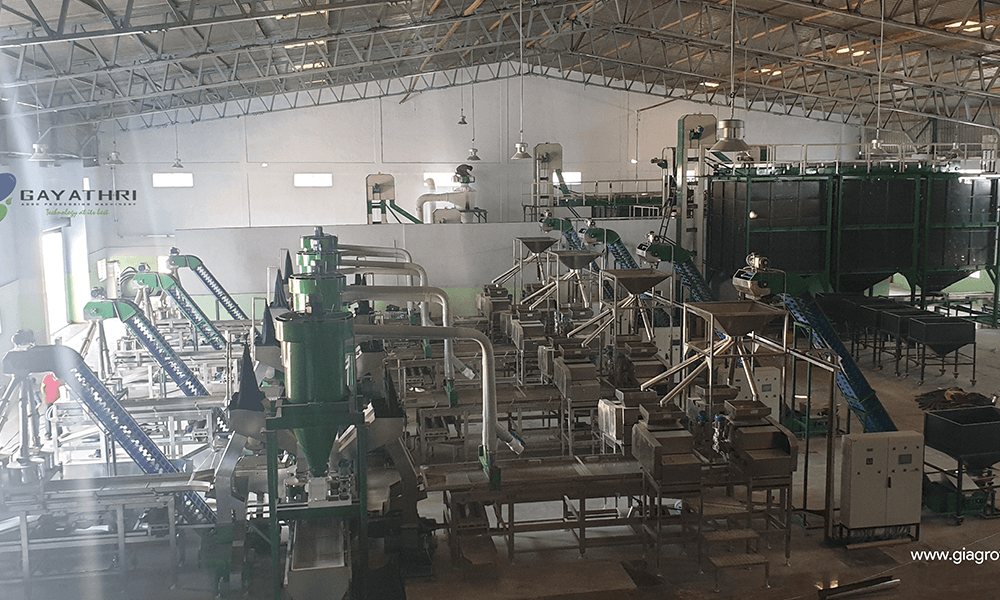

Cashew Nut Shelling Machine

The Steam cooked and air-cooled RCN are moved to Storage Silos through horizontal and vertical conveyors and kept ready for Shelling.

Manual and mechanized shelling machines are built with horizontal and vertical systems in various modes of operation

Standard Output capacity is in the range of 25kg/hr, 50kg/hr, 80kg/hr, 300kg/hr, 450kg/hr.The output capacity of an Automated shelling line is in the range of 300kg/hr, 600kg/hr, and 1200kg/hr

The mechanized shelling lines can be configured for a continuous process to separate the shells from the Kernel and mechanically scoop the kernels in the automatic system.

Raw Cashew Nut, when processed, yields about 25 % by weight of raw nut in the final stage. It varies from origin to origin as the size and inner cashew shape and size differ.

Shelled RCN produces Kernels and Shells during the shelling process. Therefore, the oily shells need to be separated from the kernels immediately after shelling to avoid oil contamination of kernels.The Shelling machine output passes through a perforated vibratory deck to separate kernels from the shells.The lightweight shells are sucked out through a Pneumatic aspirator and carried away for further storage/use and disposal.

The cut shells are used to produce Cashew Nutshell Liquid (CNSL) which is widely used in the polymer industry, and Shell cake is used as burning fuel.

Heat Treatment Of Unpeeled Cashew Kernel (Borma Treatment)

Once the Cashew Kernels are removed from the shells, the kernels need to be dried by hot air treatment to loosen the non-edible red skin (testa) of the Kernel for easy Peeling.

The skin on kernels is heated uniformly in tray dryers. This heating system also preserves the original color of the Cashew kernel and the quality of the Kernel.

Humidification Of Unpeeled Cashew Kernel

The Borma treated cashew kernels are humidified (moisturized) by water mist spray. The Cashew kernel trays are kept in trolleys for conditioning and humidified in a closed room. Steam is injected instead of water mist for accelerated humidification in a short time.

The humidified Kernel's brown skin (testa) undergoes shrinkage due to sudden cooling, which dislodges the hold (adhesion) of the skin to the Kernel.

Peeling Of Cashew Kernel

The Cashew kernel conditioned as above is now ready for peeling. The Peeling of the testa is done by hand for smaller-scale production or through mechanized Pneumatic air peelers. Usage of sharp edges of a knife is discouraged as it causes scrapping of kernels. Such scrapping mars (spoils) the look/appearance of the Kernel and is more pronounced after oil roasting.

Pneumatic air peelersare used for mechanized Cashew kernel peeling. The system leaves some percentage of partially peeled kernels. The partially peeled kernels are sorted from fully peeled kernels by Optical color sorters for re-peeling or manual Peeling.

Skilled labor peels approximately 6 to 8 kg in a day.Pneumatic peelers can peel up to 300 kg per hour. The Peeling of cashew kernel yields about 9 % skin by weight of Kernel.

The primary grading of kernels into whole, broken, and rejection are done at this stage.

Grading Of Cashew Kernel

Cashew kernels are graded based on shape, size & color as per International Specification and Standards. The Grade Specification & Color chart issued by The Cashew Export Promotion Council of India has been recognized worldwide.

Usually, skilled labor can grade anywhere between 20 to 50 kg of Cashew kernel per day depending on the size /shape of the Cashew kernel. Mechanized wire mesh sieves are used in grading broken kernels into Large White Pieces(LWP), Small White Pieces(SP), and Baby Bits(BB).

Optical color sorters are used to final grading kernel to international standards with very high accuracy and speed.

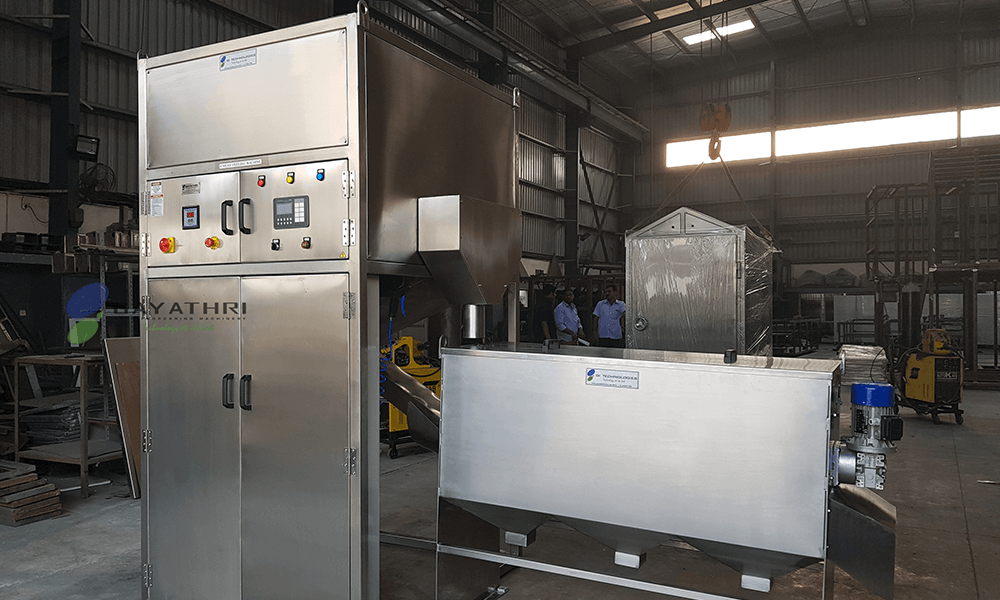

Conditioning Of Graded Cashew Kernel

The moisture percentage permitted in the graded Cashew kernel is 3 to 5 % by weight at the time of Packing. A higher moisture level above 4 % during final Packing is not preferred as the same may cause fungi and aid infestation. On the other hand, a low moisture level is undesirable as it causes Kernel breakage during shipment.

To reduce excess moisture levels, cashew kernels are heat treated. Then, they are humidified to increase moisture to the required level, if needed. The final moisture level is maintained between 3 to 4 %.

Filling And Packing

Graded and moisture conditioned cashew kernels are filled in 18 Litre Square Tins, 25 lb.Standard Net Tin weight is 25 lb. (11.34 kg).

The weighed tins are "Vita packed."This ensures the prevention of infestation in a packed tin container and increases the shelf – life of Cashew kernel during shipment & storage until it is consumed.

Vita packing is the process of vacuuming and injecting inert gas, viz. Carbon dioxide or Nitrogen into the Cashew kernel-filled tins. Then, the inert gas-infused tins are hand soldered to fix the lid hermetically using lead-free solder.

Flexible packaging of Cashew kernel in Pouches for shipment with a facility to gas flush with an inert gas after vacuuming using the semi-automatic electronically controlled machine has replaced tin packing.