RCN Steam Boilers & Cookers

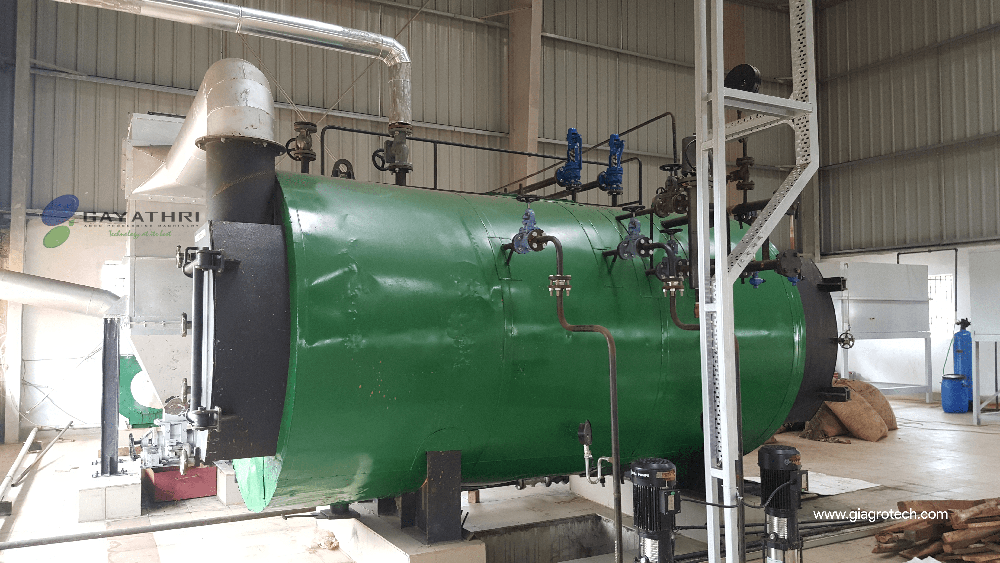

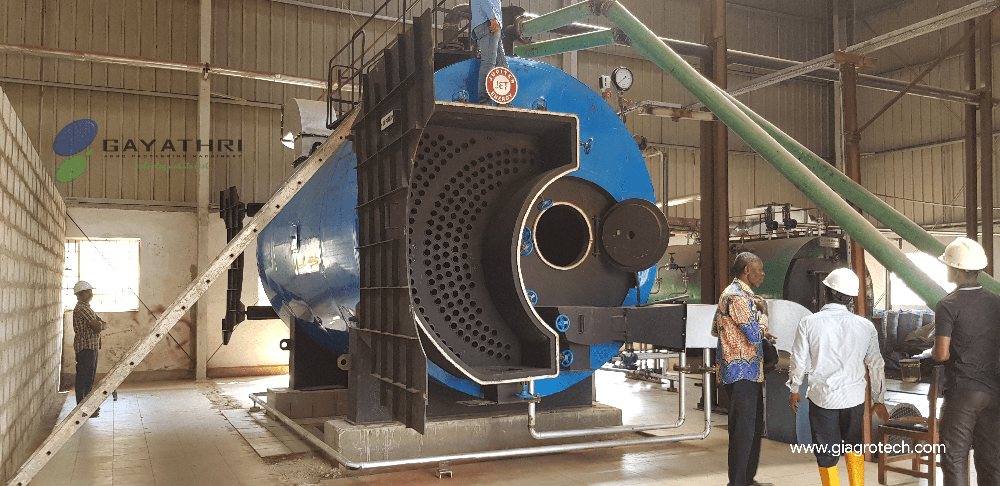

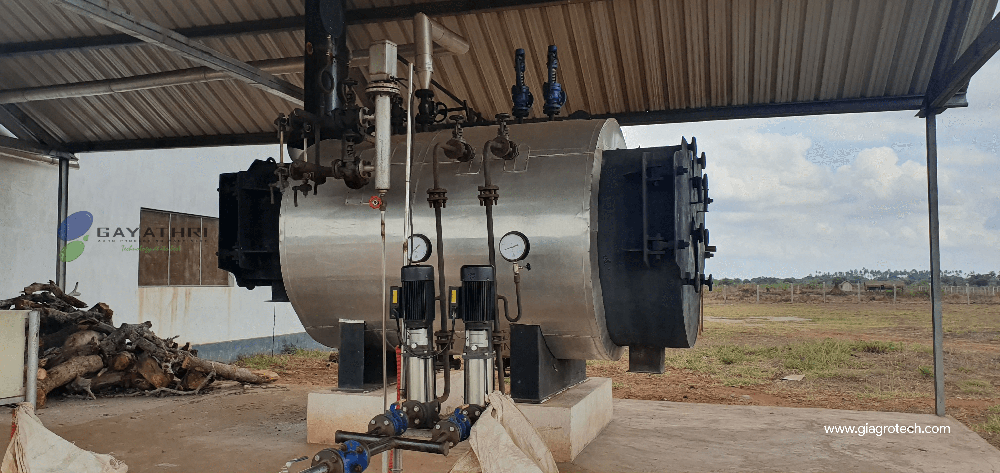

BOILERS

Boilers are used to generate Steam in RCN processing for Steam cooking of RCN and heating of air in tray driers through heat exchangers. Further, Steam is also used for the humidification of Kernels before peeling.

Boiler steam production capacity is chosen depending on the steam requirement for the process. Available steam production capacity range is 100kg/hr to 6000kg/hr

Commonly RCN shell cake is used along with wood waste as boiler fuel. The gasifier can be used to burn Shell/Wood waste without smoke.

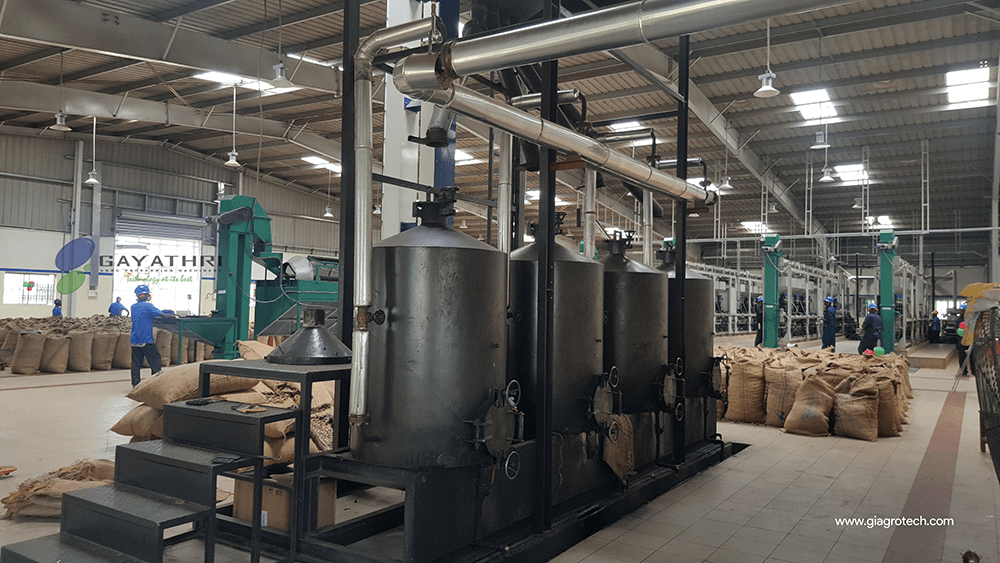

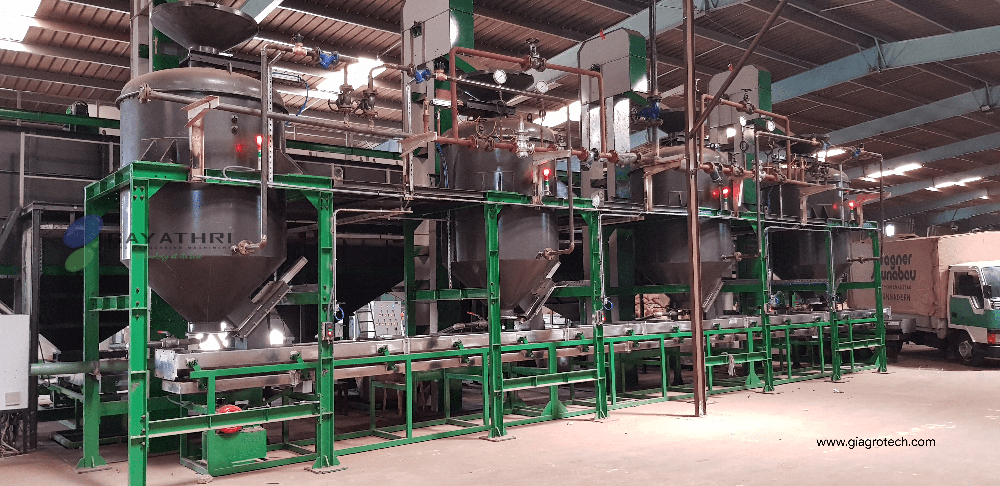

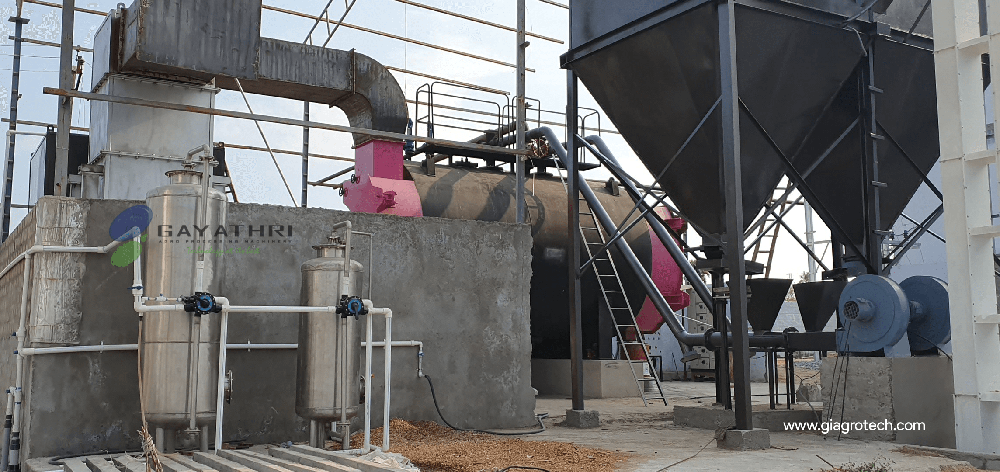

STEAM COOKERS

Raw Cashew Nut (RCN) is steamed/cooked before shelling to make it amenable to the shelling process.

Steam cookers are available in various capacities to suit the process requirement. Also, a mechanized feeding system is available for cooking. For large cookers, the output is conveyed through conveyers to cooling silos.